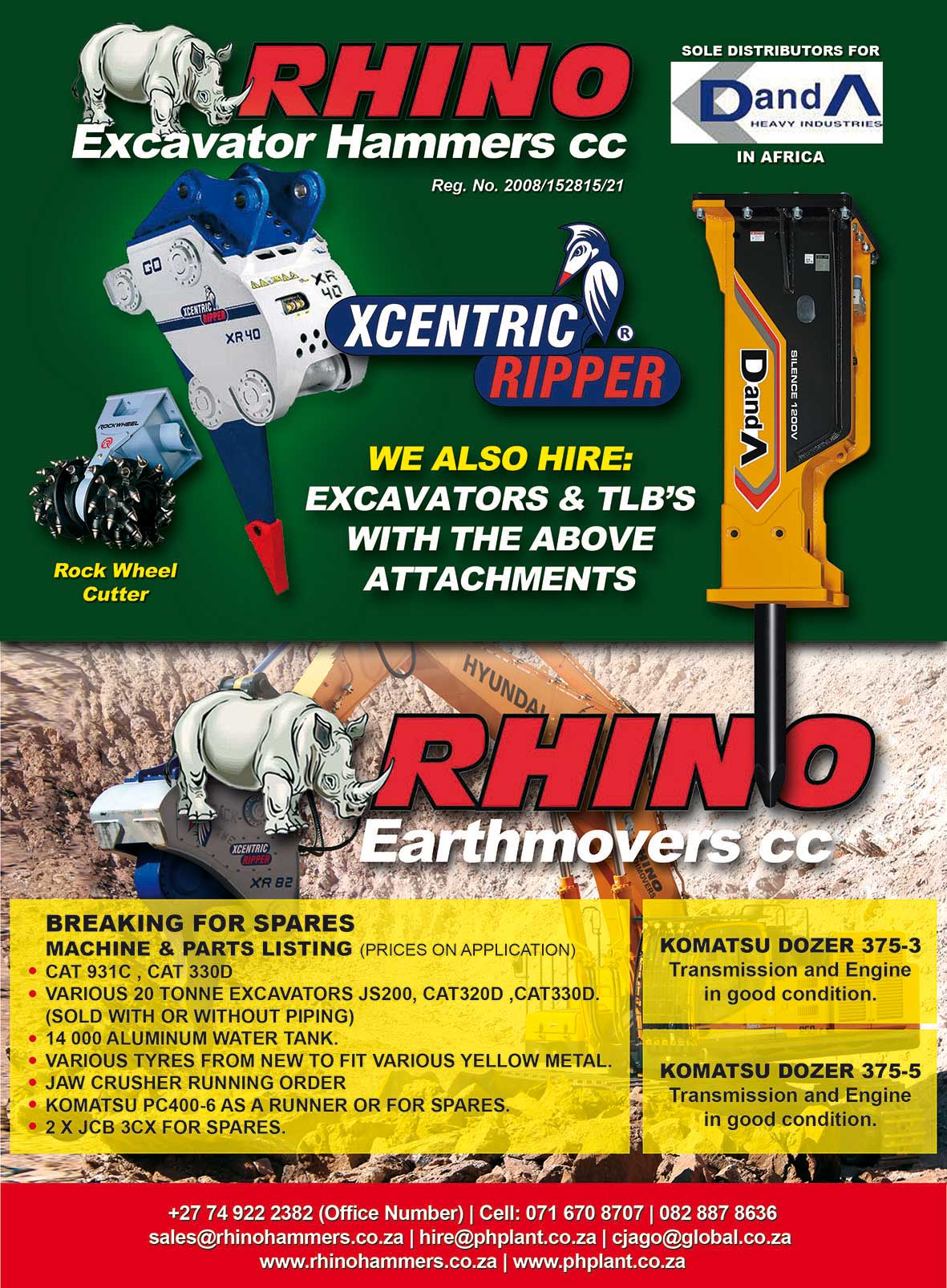

D&A Range

Established over a decade ago

Rhino Excavator Hammers are the sole Sub Saharan Africa agents for D&A Hammers

D&A have developed a reputation for manufacturing products that meet modern production demands through hi-tech design and excellent quality material construction. Ease of servicing makes them ideally suited to the hard breaking material demands and applications in Africa.

D&A Hammers are sold in over 43 countries worldwide through a network of international distributors.

D&A are OEM’s for leading European Earthmoving Machinery Manufacturers.

Rhino’s mission is to keep clients hammers working by offering fast servicing turn-around time with technical back-up and advice.

Rhino stocks a full range of hammer tools, including moil point, chisel point and flat foot. Rhino carry a complete range of spares to service clients hammers and support field servicing teams.

Below are examples of fast moving breakers that we supply in South Africa. A proven product worldwide used by major players in the mining and construction industry. Encompassing all excavator sizes.

If you would like to see more on D and A heavy industries,

please visit: www.dandaheavyindustries.com

Advantages of D&A Hydraulic Breakers

- Auto-Stop (Anti-Blank Fire) System This function ensures less problems with the component and longer life of the hydraulic breaker.

- Upper Level of Through Bolt The size of the through bolt is larger than other makers which reduces breakages and to avoid loss of tightness.

- Accumulator Build Choice Accumulator avoids stress on hydraulic components and absorbs pressure fluctuation inside the breaker.

- A wider range of model sizes avoids less compromise relating to machine sizes.

- All Silenced suppressed hammers across the entire model range.

- D and A technology patents throughout the range

Look at the spec sheets below for a model that will suit your needs:

| Model | D&A 6V | D&A 8V | D&A 17V |

|---|---|---|---|

| Operating Weight | 55(121) | 120(265) | 187(412) |

| Required Oil Flow | 18~25(4.75~6.6) | 15~30(3.96~9.25) | 23~70(6.07~18.50) |

| Operating Oil Pressure | 60~130 | 90~120 | 90~120 |

| Tool Diameter | 40(1.75) | 45(1.77) | 57(2.24) |

| Suitable Excavator | 0.5~2 | 0.8~2.5 | 1.5~4.0 |

| Model | D&A 40V | D&A 60V | D&A 70V |

|---|---|---|---|

| Operating Weight | 260(572) | 330(728) | 495(1,091) |

| Required Oil Flow | 30~60(7.92-15.84) | 40~80(10.16~20.32) | 45~100(11.89-26.4) |

| Operating Oil Pressure | 110~165 | 120~165 | 40~170 |

| Tool Diameter | 70(2.75) | 75(2.95) | 80(3.15) |

| Suitable Excavator | 2.0~4.5 | 4.5~8.0 | 4.5~8.0 |

| Model | D&A 80V | D&A 100V | D&A 130V |

|---|---|---|---|

| Operating Weight | 545(1.2) | 800(1.764) | 900(1.985) |

| Required Oil Flow | 50~100(13.21~26.42) | 75~120(19.8~31.70) | 80~140(21.12~36.96) |

| Operating Oil Pressure | 140~170 | 140~180 | 140~180 |

| Tool Diameter | 90(3.54) | 95(3.74) | 105(4.13) |

| Suitable Excavator | 6.0~10.0 | 8.0~12.5 | 10~15 |

| Model | D&A 150V | D&A 180V | D&A 200V | D&A 220V |

|---|---|---|---|---|

| Operating Weight | 1.150(2,535) | 1,450(3,197) | 1.580(3,484) | 1.800(3.968) |

| Required Oil Flow | 100~150(26.4~39.6) | 100~155(26.4~40.92) | 120~170(31.68~44.8) | 12~190(31.70-50.19) |

| Operating Oil Pressure | 160~190 | 160~190 | 160~190 | 160~190 |

| Tool Diameter | 115(4.52) | 125(4.59) | 135(5.31) | 135(5.31) |

| Suitable Excavator | 12~18 | 16~22 | 18~24 | 20~26 |

| Model | D&A 300V | D&A 360V | D&A 450V | D&A 550V |

|---|---|---|---|---|

| Operating Weight | 2,400(5,292) | 2,700(5,954) | 3,300(7,277) | 3,800(8,379) |

| Required Oil Flow | 180~240(47.52~63.36) | 200~260(52.8~68.64) | 220~280 (58.08~73.92) | 240~320(63.36~84.48) |

| Operating Oil Pressure | 250~380 | 160~190 | 160~190 | 160~190 |

| Tool Diameter | 150(5.90) | 155(6.10) | 165(6.50) | 175(6.88) |

| Suitable Excavator | 52.8~79.2 | 28~42 | 34~50 | 40~60 |

| Model | D&A 650V | D&A 700V | D&A 750V | D&A 1200V |

|---|---|---|---|---|

| Operating Weight | 4.500(9.921) | 5700(12.566) | 7000(41215.435) | 10000(22046) |

| Required Oil Flow | 260~360(68.68~95.10) | 310~390(81.89~103.03) | 360~450(95~119) | 450~530(118.87~140.01) |

| Operating Oil Pressure | 150~190 | 170~210 | 160~190 | 160~190 |

| Tool Diameter | 180(7.09) | 200(7.87) | 175(6.88) | 205(8.26) |

| Suitable Excavator | 45~80 | 55~60 | 60~100 | 240 |